Technology asset for Vulcan VULSORB®

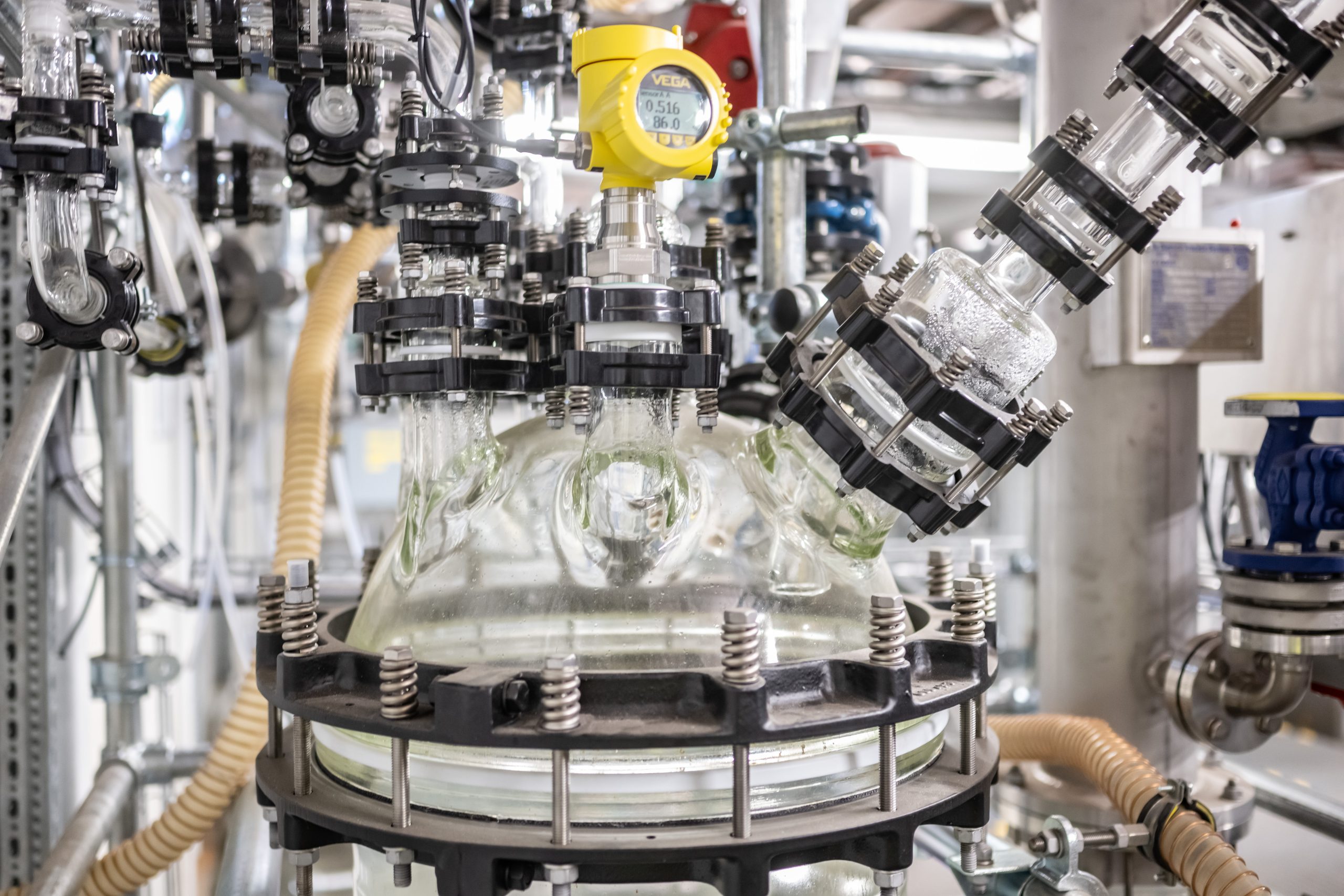

To efficiently produce lithium from subsurface brine, Vulcan has developed its own in-house aluminate-based sorbent VULSORB® to capture the lithium before the brine is returned to the subsurface. VULSORB® has the potential to be a technology asset for Vulcan and is a testament to our team’s commitment to build value in-house.

In-house lithium extraction technology VULSORB®

Vulcan has successfully developed, tested, and demonstrated its own in-house lithium extraction sorbent VULSORB®. The aluminate-based sorbent shows higher performance and lower water consumption for lithium extraction compared to commercially available sorbents. To achieve better optimisation, create IP value in-house and control over its process and supply chain, Vulcan has developed its own proprietary sorbent, VULSORB®, which is synthesised via a standard 3–step process. This highlights Vulcan’s strong passion for innovation and underlines the Company’s pioneering spirit.

Based on test results achieved, Vulcan decided to use a sorbent with lithium aluminate intercalate structure for the A-DLE process. VULSORB® uses and improves on the same A-DLE technology that has been used commercially for over two decades, and currently accounts for 10% of global lithium production.

VULSORB® Summary Presentation Q2, 2025

Vulcan is driving the future of sustainable lithium production. By combining environmentally friendly Adsorption-Type Direct Lithium Extraction with a renewable heat source, we achieve highly efficient, low-cost and carbon-neutral lithium production. With our proprietary lithium extraction technology VULSORB®, we optimise this process further.

Discover more about our sustainable approach in our latest VULSORB® Summary Presentation.

Technology asset Self-developed

De-risking A-DLE on Upper Rhine Valley Brine Our activities

- Optimisation plants in operation: Learn more here.

- Technology selected in scoping work 2018-2020

- Three years of in-house laboratory test work successfully completed 2021-2023

- Technology de-risked on our brine chemistry at multiple producing well sites

- 5000+ cycles in 2.5 years of stable, non-stop operation

- Larger pilot plant P1A in operation since autumn 2022, with total 2000+ cycles of operation

- Data from pilot plants used to optimise and complete engineering design for Definitive Feasibility Study and Bridging Phase.