Successful lithium production Vulcan Plants.

Vulcan is building several plants to execute its integrated lithium and renewable energy project.

Lithium Extraction Pilot Plant Vulcan pilot plant.

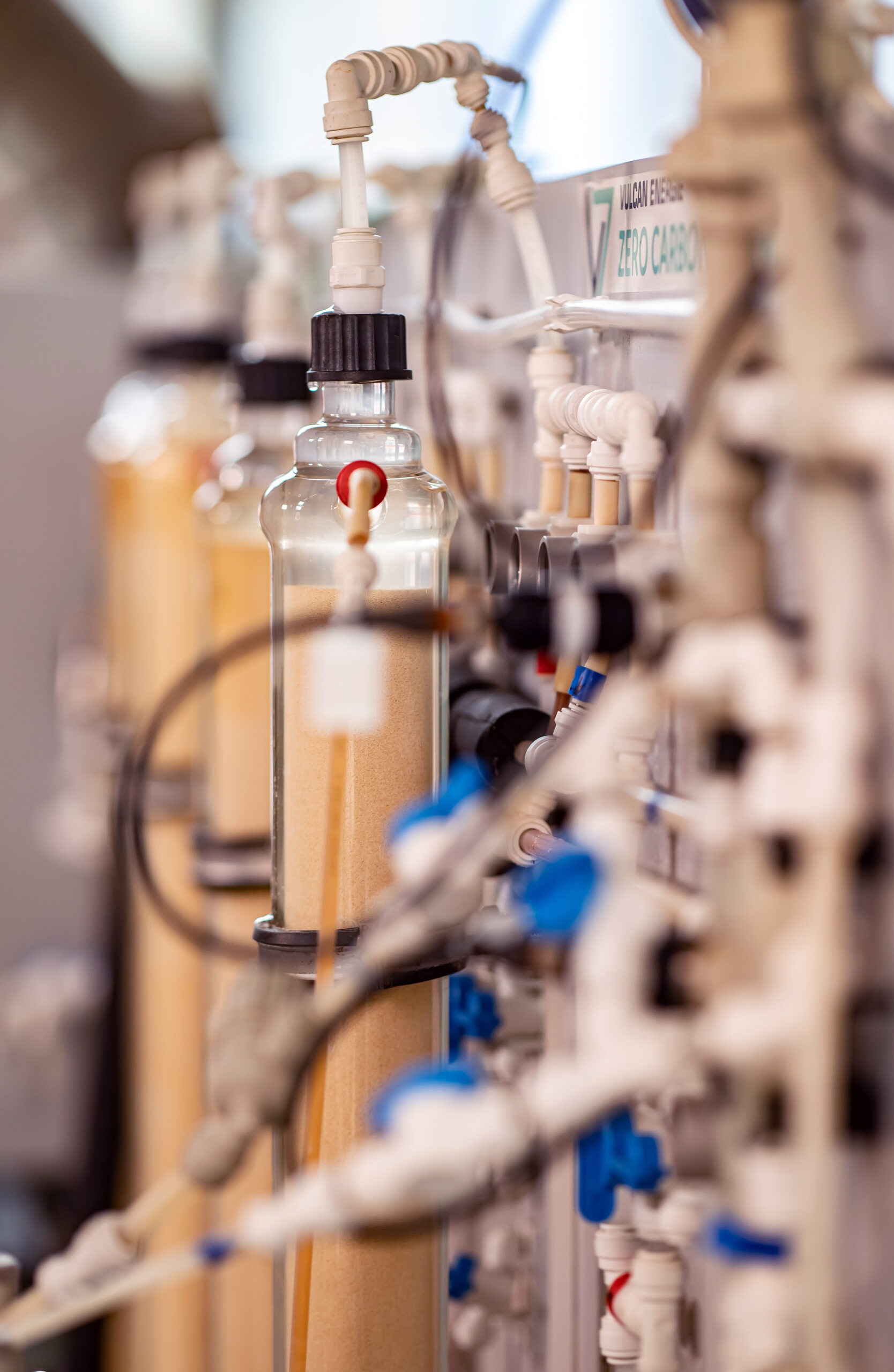

Since the beginning of 2021, Vulcan’s Lithium Extraction Pilot Plant has been in continuous and successful operation at multiple well locations to de-risk the lithium production process. The aim of operating the pilot plant was to test and optimise the process of Direct Lithium Extraction with our sorbent VULSORB®.

- 10,000 hours of successful in-house pilot plant performance

- Showing more than 90% lithium recoveries

- 1000 cycles of sorbent life with no degradation

Lithium Extraction Optimisation Plant Vulcan LEOP.

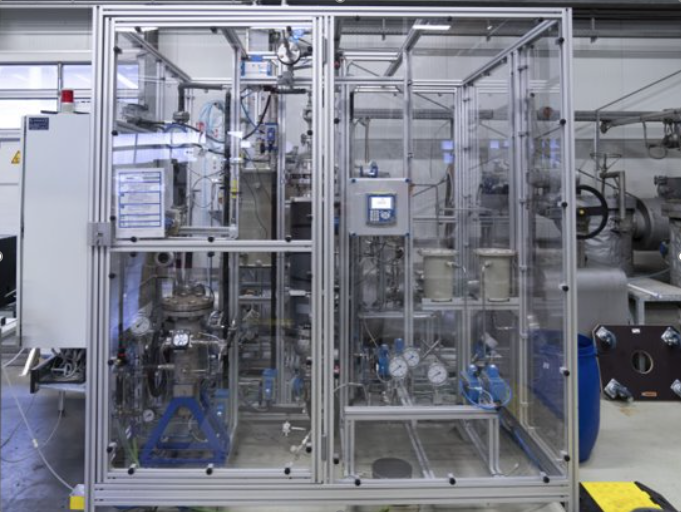

In April 2024, Vulcan has started the production of the first lithium chloride (LiCl) from the Lithium Extraction Optimisation Plant (LEOP). This is the first LiCl domestically produced from a local source with an entirely locally sourced value chain in Europe, for Europe.

Early results have consistently recorded over 90% (up to 95%) lithium extraction efficiency from its A-DLE unit, which is in line with expectations.

Representing a more than €40m investment by Vulcan, LEOP is an optimisation, operational training and product qualification testing facility designed to enable operational readiness for when the Phase One Lionheart commercial facility is completed.

LEOP builds on over three years and more than 10,000 hours of successful in-house A-DLE piloting both in the Vulcan labs and at its pilot plants in Insheim and Landau.

- April 2024: Start of production (SOP), Vulcan has produced the first lithium chloride (LiCl) from its Lithium Extraction Optimisation Plant (LEOP).

- This is the first LiCl domestically produced from a local source in Europe, for Europe.

- LEOP is showing strong early results consistently over 90% (up to 95%) lithium extraction efficiency from its Adsorption-type Direct Lithium Extraction (A-DLE) unit.

- The SOP follows over three years and more than 10,000 hours of successful in-house A-DLE piloting by Vulcan, showing high lithium recoveries and thousands of cycles of adsorbent life with no material degradation.

- Vulcan’s LEOP facility is equipped with world-leading technology designed to showcase the efficiency of our A-DLE process and environmental benefits, whilst training our commercial production team in a pre-commercial environment as we build the Phase One commercial plant.

- LEOP is delivering production efficiency that is in line with expectations.

- Once Lionheart commercial production commences, it is estimated that Vulcan’s integrated lithium and renewable energy business will produce enough lithium for approximately 500,000 EVs.

Find a video of LEOP’s start of production here.

The LiCl produced by LEOP represents the first lithium chemicals fully produced from a locally sourced raw material, i.e. extracted and then processed locally, at this plant scale in Europe. During hot commissioning and startup of LEOP, a generic aluminate-based lithium adsorbent was used, that has been used before in Vulcan’s lab and pilot plants. Vulcan’s high-performance aluminate-based lithium adsorbent VULSORB® is used for the long-term operation. The LiCl product (40% weight solution) produced from LEOP is transported to the Höchst Industrial Park in Frankfurt-Höchst, where Vulcan’s downstream optimisation plant CLEOP is located. At CLEOP, LiCl is converted into battery-grade lithium hydroxide monohydrate (LHM).

In January 2025, Vulcan has produced the first battery-quality LHM at its CLEOP, representing the first fully integrated, battery-quality LHM produced in Europe, from raw material to final product.

These optimisation plants are analogous to Vulcan’s Phase One commercial plants, with similar process flowsheets. The commercial project is aiming for 24,000 tonnes per annum of lithium hydroxide production capacity, the financing process of which is currently being led by BNP Paribas.

Central Lithium Electrolysis Optimisation Plant Vulcan CLEOP.

At Vulcan’s pre-commercial downstream optimisation facility CLEOP, we process the lithium chloride solution from our upstream plant LEOP in Landau into lithium hydroxide for the production of electric vehicle batteries. Since the beginning of November, the plant is officially opened and producing the first sustainable lithium hydroxide from raw material to end product in Europe, representing a big step for Europe’s independence from raw materials and for the transition to sustainable, electric transportation.

In January 2025, Vulcan has produced the first battery-quality LHM at its CLEOP, representing the first fully integrated, battery-quality LHM produced in Europe, from raw material to final product. Battery-quality LHM from CLEOP will be used in ongoing qualification processes with Vulcan’s European focused offtakers, including Stellantis, Renault, LG and Umicore, whilst Vulcan’s Phase One project is being constructed.

LEOP and CLEOP will serve as important process optimisation and training facilities, in preparation for the Company’s commercial operations.

Renewable energy plant Vulcan Geothermal Plant.

In 2022, Vulcan acquired the Insheim geothermal power plant from Pfalzwerke AG and has successfully operated the facility since. The plant has been in operation since 2012, supplying around 6,500 households in Insheim with renewable power.

Initially planned to produce mostly power, Vulcan’s geothermal plant will increase heat production over time.

In addition, Vulcan is negotiating a heat offtake agreement with the City of Landau to help them to decarbonise and localise their heat supply and move away from fossil gas.

Lithium Extraction Plant Vulcan LEP.

Phase One commercial Lithium Extraction Plant

- Positive support from Landau City Council: The Council voted with a majority in favour of the land development plan for the industrial estate containing Vulcan’s Phase One Geothermal Lithium Extraction Plant (G-LEP) location.

- LEP will be constructed next to new Lionheart Geothermal Plant in Landau.

- Total targeted capacity to be 24,000tpa LHM equivalent in LiCl form.

- From the LEP, LiCl solution will be transported to the CLP at the Industrial Park Höchst (Frankfurt).

- Modular build allows for further phased development across other phases in Upper Rhine Valley Brine Field (URVBF).

Central Lithium Plant Vulcan CLP.

- CLP planned to be located in Frankfurt at the Höchst Industrial Park. Close to 100,000sqm already secured.

- Targeted 24,000tpa LHM capacity with space for further modular expansion.

- Conversion of LiCl to battery grade LHM using electrolysis. Only by-product (saleable) is HCl. Significant synergies with existing chlor-alkali producers in the same chemical park, e. g. Nobian.

- Recycle of purge streams back to LEP – low waste.

- Höchst is one of Europe’s largest industrial estates and is home to around 90 chemical and pharmaceutical companies.

- Infraserv (industrial park operator) contracted to supply power, utilities and services.

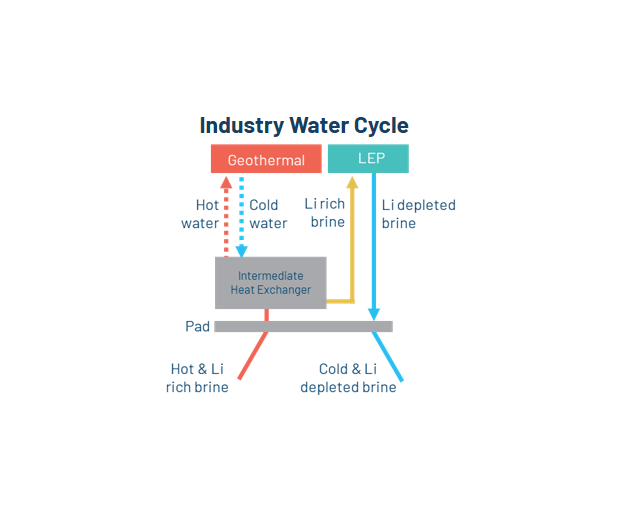

Industry water and brine cycle piping Site infrastructure.

- Vulcan will use intermediate heat exchangers at each well site to efficiently transfer heat from geothermal brine into a closed-loop industrial water cycle. This system will send hot water via pipelines to the district heating facility and Organic Rankine Cycle (ORC) plants. After the heat is utilised, the cooled water is recirculated back to the heat exchanger for reheating.

- Simultaneously, the cooled lithium-rich brine is directed from the heat exchanger to the Lithium Extraction Plant (LEP) for the lithium extraction to occur. The lithium-depleted is then reinjected into the reservoir, completing the cycle.

- This innovative approach offers significant operational advantages. By using clean industrial water for district heating and ORC systems, the risk of scaling is eliminated. Additionally, cooling the brine before it enters the pipeline and LEP greatly minimises scaling potential, enhancing system efficiency and reliability.