Providing a domestic and sustainable supply of lithium Sustainable Lithium Business.

We are aiming to become Europe’s leading integrated sustainable lithium business and enabling energy security through geothermal energy.

Integrated renewable energy generation and lithium production Competitive advantage.

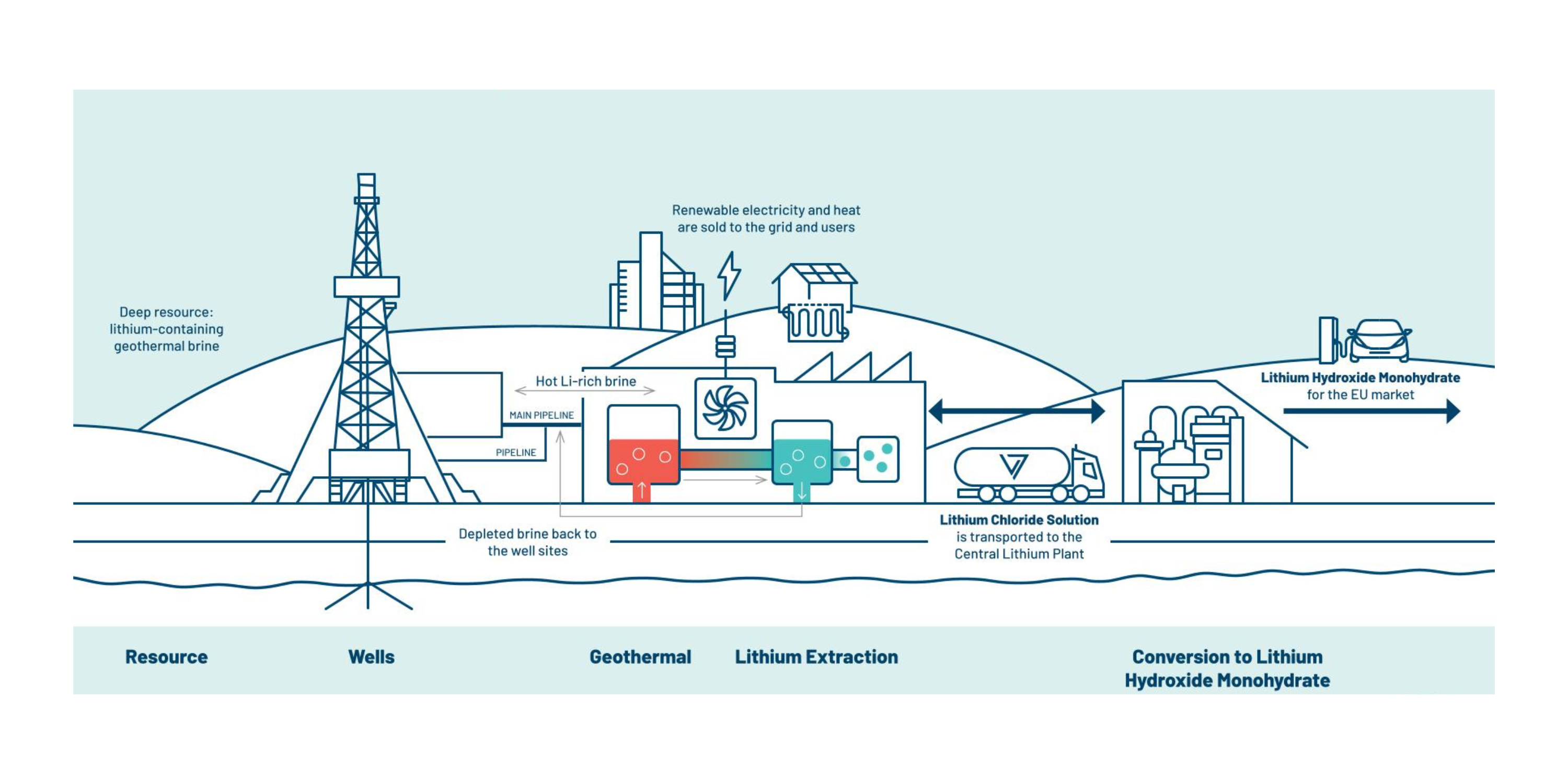

Vulcan Energy uses a simplified two-stage process to convert lithium-rich brine into a battery-ready product. This commercially leading, Adsorption-type lithium production is powered by renewable heat, with renewable energy supplied directly to the grid and lithium delivered straight to offtake partners.

- Components: Well sites, Interconnected Pipeline and

Power (ICPP) - Process: drilling

- Outputs: geothermal lithium-rich brine

Vulcan’s in-house drilling team, Vercana, drills geothermal wells, with electric drill rigs powered by the local grid, with the geothermal brine transported through the ICPP.

- Components: Geothermal & Lithium Extraction Plant (G-LEP) geothermal power plant & ICCP

- Inputs: hot industrial water transported via ICPP

- Outputs: both geothermal energy and heat

Hot industrial water is transferred to the geothermal power plant, where geothermal power and heat are produced and transferred to the electricity grid and district heating networks.

- Components: G-LEP, ICPP

- Inputs: brine transported from well sites via ICPP to G-LEP

- Outputs: Lithium chloride

- Process: A-DLE , VULSORB®

After being transported to Vulcan’s G-LEP via the ICPP, lithium chloride is produced from the geothermal brine using VULSORB® and natural waste heat from the brine.

- Components: Central Lithium Plant (CLP)

- Inputs: Lithium chloride, (geothermal heat to heat brine)

- Outputs: lithium hydroxide monohydrate (LHM)

- Process: electrolysis

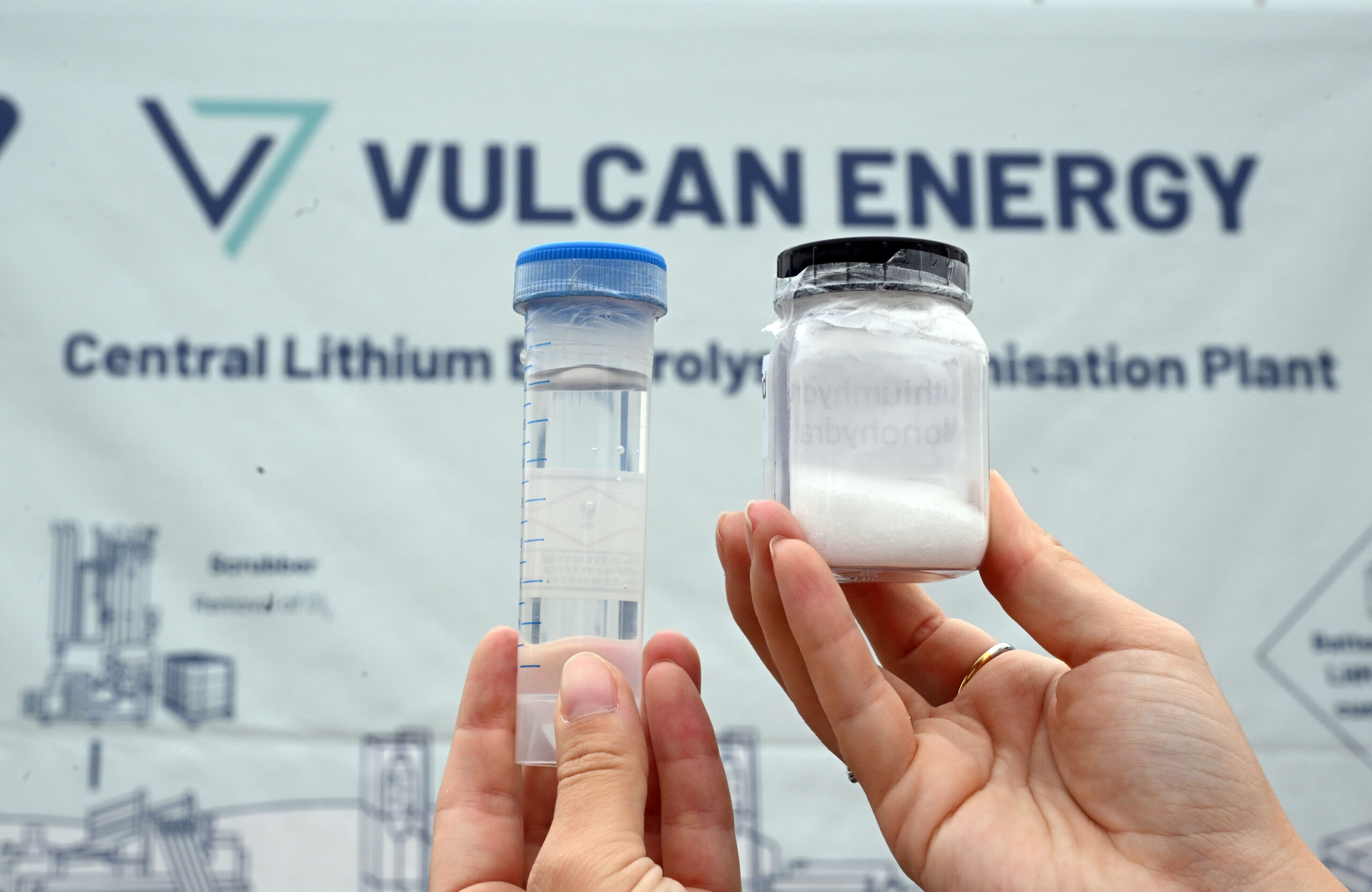

The lithium chloride is transferred via trucks to the CLP located at the Höchst Industrial Park where, through electrolysis, it is converted into lithium hydroxide monohydrate (LHM). Finally the LHM is delivered to offtakers for use in EV batteries.

Integrated lithium and renewable energy project for the EV transition.

Lithium is a critical metal in electric vehicle (EV) batteries, playing a vital role in the transition to sustainable transportation. With the European Union mandating that all new cars be 100% electric by 2035, Europe’s lithium demand for electric vehicles is projected to exceed one million tonnes annually by 2030 — surpassing the size of today’s entire global lithium market. Vulcan aims to be the largest, most sustainable supplier of lithium chemicals and renewable energy from Europe, for Europe, to empower a carbon neutral future.

Unprecedented demand The role of Lithium.

Lithium is a critical raw material, indispensable as a component of batteries for electric transportation. However, to date there is no local integrated supply of lithium hydroxide in Europe to meet demands. Strategically placed in the heart of the European electric vehicle market, we are rapidly advancing out integrated lithium and renewable energy project to target timely market entry, with the ability to expand to meet the unprecedented demand that is building in the European markets.

“We are aiming to become Europe’s first producer of domestically produced lithium, and the world’s first producer of sustainable lithium hydroxide for electrical vehicle batteries.”

Growing wave of sustainable lithium supply VULSORB®: Enabling sustainable lithium.

Vulcan’s approach to lithium production creates a more sustainable and environmentally friendly solution: Adsorption-type Direct Lithium Extraction (A-DLE)

This method is as simple as it is proven.

Uniquely, the Company utilises geothermal energy to drive the lithium extraction process. Geothermal heat has been used for years to generate renewable energy by bringing hot brine from underground to the surface, producing heat and power, and then returning the brine to the subsurface. As the brine is not only hot but also contains significant amounts of lithium, the metal is captured within the in-house developed sorbent VULSORB®, before the brine is returned to the subsurface. This closed-cycle process not only produces lithium but also generates excess renewable energy, benefiting local communities.

By combining geothermal energy and A-DLE, Vulcan’s approach stands out with key environmental credentials: Unlike conventional methods that emit between 10 and 30 tonnes of CO2 per tonne of lithium hydroxide, Vulcan emits net zero tonnes of CO2, according to Life Cycle assesment studies. Additionally, legacy methods of lithium production consumes large quantities of water and land, while Vulcan’s process is significantly more efficient in resource usage, consuming only 1.6 tonnes of water net of products, and 6m2 of land per tonne of lithium hydroxide produced. Learn more about our sustainability credentials.

In a world where automakers like Stellantis or Renault are actively seeking clean and sustainable sources of raw materials for lithium-ion batteries, Vulcan’s innovative approach offers a promising solution that aligns with environmental, social, and governance (ESG) principles. It represents a major step towards more sustainable and responsible lithium production for the growing electric mobility industry. Learn more about Adsorption-type – Direct Lithium Extraction.

We are ready to deliver Phase One.

Vulcan integrates renewable heat and power generation with sustainable lithium extraction and lithium hydroxide conversion to support Europe’s growing electric vehicle (EV) industry. Phase One targets approximately 24,000 tonnes of lithium hydroxide production annually — enough to power around 500,000 EVs each year.

Strategically placed Focus Europe.

Europe’s transportation sector is undergoing a significant transformation, driven by the rapid growth of electric vehicle (EV) sales. From 2035, all new cars and vans registered in the European Union are set to be net zero emission.

This shift towards carbon neutral mobility is accelerating the expansion of Europe’s lithium-ion battery production capacity, with direct implications on the demand for lithium:

- As 2035 approaches, Europe’s need for lithium hydroxide will increase to meet the demand from Europe’s automakers.

- Zero local supply of lithium hydroxide: ~80% reliant on China.

- The current lithium supply is CO2-intensive but western automakers want and need low carbon sources. Vulcan’s integrated lithium and renewable energy project is aiming to reduce this heavy reliance on China for the supply of battery-grade lithium compound.

Europe is one of the fastest growing electric vehicle manufacturing markets in the world. It is exponentially increasing its domestic lithium-ion battery production capacity to meet this demand, making it also the fastest growing lithium market in the world. Predictions indicate Europe will need more than twice of what the entire global market produces today.

Strategically placed in the heart of the European electric vehicle market also gives Vulcan significant sustainable advantages:

- The European Commission has called for all electric vehicles to have a certificate indicating the total greenhouse gas emissions the vehicle produces.

- The European Commission requires ‘CO2 Passports’ for all electric vehicles, detailing their full CO2 impact whereby Volkswagen, Stellantis and other European automakers are placing greater emphasis on creating a sustainable supply chain for their cars.

- The current lithium supply chain does not cater for low carbon production processes. Our integrated lithium and renewable energy project fills these gaps in the market and enables Vulcan to make a significant contribution to Europe’s target of reaching net zero emissions by 2050.